Break Detection

(Available only in the DFS3 Series gauges)

Break detection has two distinct uses:

1. As a Test Stop condition

When a test is running with the stop condition set to 'On Break', it will stop that test if the conditions defined in Break Detection settings have been met.

2. As a Test Result for Breaking Force (T-BRK or C-BRK)

This function is especially useful with samples that characteristically yield before they actually break.

The DF3 Series gauge will report the following as part of a Break Detect test:

- Break Load

- Peak Load (T-PK or C-PK)

The DF3 force gauge allows you to perform two different methods:

It is important to note that the DF3 gauge will need to be zeroed in between each test that uses break detection for the break detection to be applied to the next test.

Sharp Break

The Sharp Break method is used for detecting very quick and large changes in force readings. The internal algorithm checks for a number of load changes within defined periods of time. This is normally reserved for a fast acting break in a sample under test.

Percentage Break

The Percentage Break method is ideal for tests where the drop in force is gradual, due to slower failure under load. The Percentage Break test allows the user to specify a % Drop from the Peak Load.

Example: Set the Percentage Drop to 80%: The DF3 gauge will determine the Break Load when the current load measured reaches 80% of the last recorded Peak Load value.

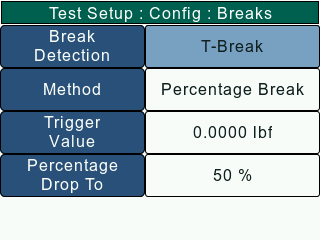

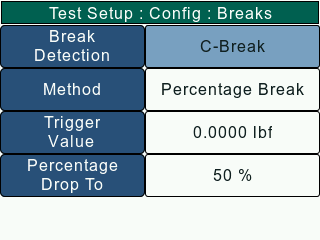

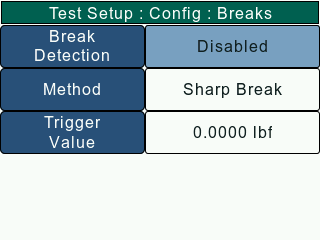

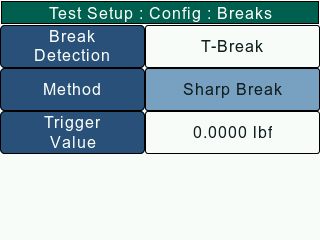

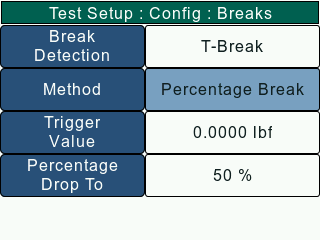

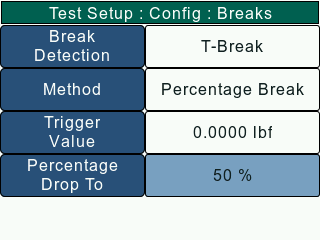

Break Detection Setup

For performing a Break Detection test, the user must enable the Break Detection from the Test Setup: Configure screen. The Break Detection screen allows the user to configure the following settings:

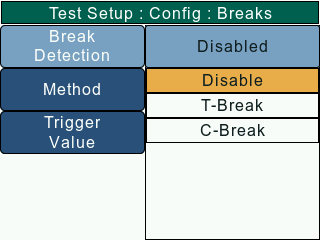

Enable/Select Mode

From the Test Setup: Config: Break Detection screen, use the navigation keys to set the cursor on the 'Break Detection' option. Press the select key to toggle between 3 options shown below. Break Detection is 'Disabled' or 'Enabled' automatically by selecting either 'T-Break' or 'C-Break'. This will define which gauge mode (Tension or Compression), that the break detection will become active over.

The Break Detection menu will offer:

- Disable

- T-Break

- C-Break

The user will have to exit the Configuration screen and save changes for the break detection settings to be applied.

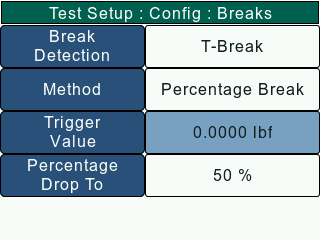

Method

On the Test Setup: Config: Break Detection screen, use the Navigation keys to set the cursor on the 'Method' option. To change the Break Detect method, press the Select key to toggle between 'Sharp Break' and 'Percentage Break'.

The user will have to exit the Configuration screen and save changes for the break detection settings to be applied.

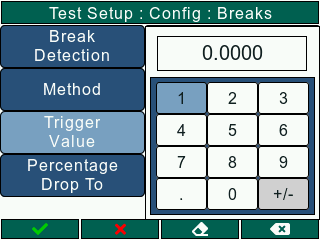

Trigger Point

The 'Trigger Point' defines the minimum force value at which the break detection function becomes active. It is important to set a correct “Break Point” based on the type of specimen and it's expected break characteristics.

If the break point is set too high, the gauge may not detect a break condition and the test being performed may not stop automatically, if the Stop condition is set for break.

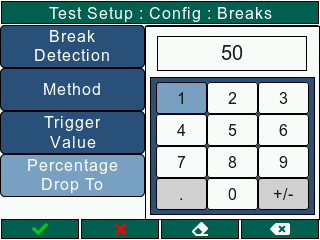

On the Test Setup: Config: Break Detection screen, use the Navigation Keys to set the cursor on the 'Trigger Point' option. Press the Select key to open the numeric keypad. Enter the required trigger force value.

The user will have to exit the Configuration screen and save changes for the trigger point setting to be applied.

Percentage Drop

The 'Percentage Drop to' value defines the percentage of the stored peak load value that the live reading must reach, for the DF3 gauge to activate the break detection. If the user defines the 'On Break' stop condition, this will automatically stop the gauge test currently running. The Percentage Break is a user-defined percentage drop. You may specify the % Drop to be from 1% to 99%, using the numeric keypad.

On the Test Setup: Config: Break Detection screen, use the Navigation Keys to set the cursor on the Percentage Drop. To set the Percentage Drop, press the Select key to open the numeric keypad.

The user will have to exit the Configuration screen and save changes for the percentage drop setting to be applied.